Vibration Isolation Mounts

What are vibration isolation mounts?

Vibration Isolation Mounts reduce vibration by isolating an object, such as a piece of equipment from the source of damaging vibrations which also lowers structure-borne noise. These are also known as isolation mounts, anti vibration mounts, rubber isolation mounts and shock mounts. SERVICE Rubber Group has a large variety of vibration isolation mounts available to fit your particular needs.

Please select a category below to browse through the Vibration Isolation Mounts, and select items to get a free quote!

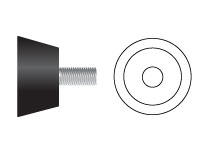

Vibration Isolation Mounts 1000 Series

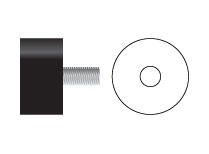

Conical Single Stud

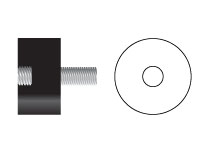

Vibration Isolation Mounts 2000 Series

Round Male & Female

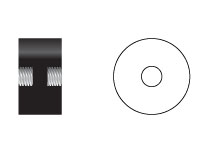

Vibration Isolation Mounts 3000 Series

Round Double Female

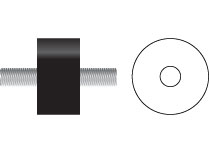

Vibration Isolation Mounts 5000 Series

Round Double Stud

Vibration Isolation Mounts 9000 Series

Round Single Stud

What are the different applications for Vibration Isolation Mounts?

Vibration Isolation Mounts can be used in a variety of OEM applications. These include Military equipment, Medical equipment, Agricultural equipment, Photo equipment,Pumps, Fans, Motors, Machinery, Compressors, Air handling equipment and Physical fitness equipment including vibration exercise machines. They also isolate vibration on a variety of products such as printed-circuit boards, delicate electronics, LED’s, LCD’s, disk drives and other smaller devices.

Does my product need Vibration Isolation Mounts?

Noise and vibration isolation is a complicated and important part of most areas of product design, engineering and development. There is often a need to reduce the transmission of vibration and damping between two elements while maintaining mechanical support. If resonance occurs in a mechanical system it can be very harmful, leading to eventual failure of the system. Vibration Isolation Mounts can protect objects and sensitive components from influencing each other, isolate or reduce annoying and potentially damaging structure-borne noise, and extended the life of the equipment or structure. Our isolation mounts are designed to accommodate appropriate shear and compression loads.

How are Vibration Isolation Mounts made?

SERVICE Rubber Group manufactures these rubber to metal frequency dampeners using several strategic rubber polymers, and we pride ourselves in our superior rubber-to-metal bonding. We produce these mounts to the Rubber Manufacturer Association, RMA standards. Vibration isolation mounts are the end product of a rubber to metal bonding process. This involves adhering rubber to a metal substrate, such as metal studs, inserts and plates. Prior to molding, the metal is degreased and sandblasted eliminating rust and other impurities existing on the metal surface. Next the metal is coated with our special bonding agent prior to being placed in the compression mold.

What options do I have with Vibration Isolation Mounts?

Our cylindrical mounts are produced with double male threaded studs, single male threaded stud, double female threaded inserts, or single female threaded insert. Our conical mounts have a single male threaded stud or single female threaded insert. These studs can be made of any metal and can be plated per customer spec. The polymers used to produce these molded rubber mounts range from natural rubber – polyisoprene, neoprene rubber – polychloroprene, silicone rubber – polysiloxane. Urethane – polyester/ether urethane to EPDM rubber – Ethylene Propylene Diene Monomer. The durometer (hardness) ranges from 28 Shore A (rubber band hardness) to 80 Shore A (automobile tire hardness).

How soon can my Vibration Isolation Mounts be delivered?

SERVICE Rubber Group stocks a wide range of standard cylindrical vibration mounts which can be delivered within one day if required. A variety of metric mounts, base plate mounts, stud and nut mounts, leveling mounts and rectangular mounts are readily available for immediate shipment. We do in-house tooling for custom molded mounts and non-standard sizes; these can be produced and shipped usually within 2 to 6 weeks.